The process of joining PPR-C pipes and fittings is very simple and results and inseparable watertight joints. It is carried out using a simple welding machine that fuses the internal surface of the fitting and the external surface of the pipe, so that the material of the pipe and the fitting will be bonded together.

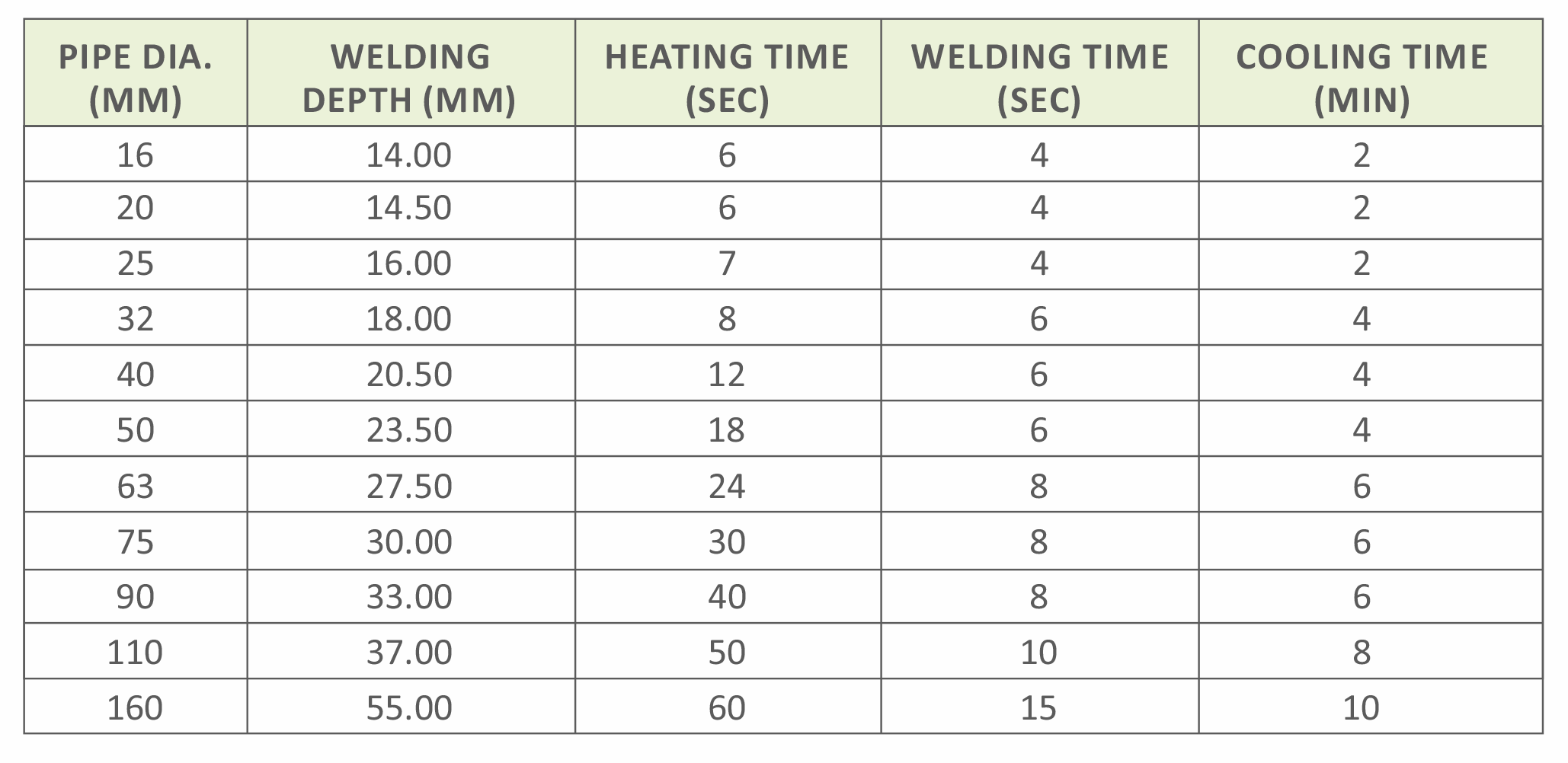

Prepare the welding machine by fitting it with the welding dies of the diameters to be welded. Connect the plug to the 220V power supply socket and wait until the green light on the machine goes out indicating the welding machine has reached the working temperature.

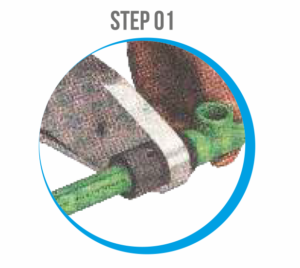

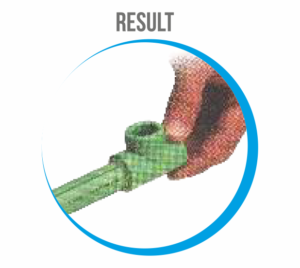

Cut the pipe at right angles to the pipe axis using suitable pipe cutter.

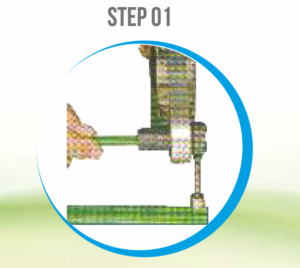

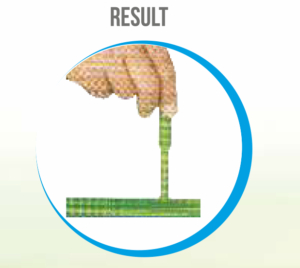

If a hole is accidentally made in the pipe (with a drill bit or screws) and if the hole is in on ly one side of the pipe, it can be repaired using the hole repairing die, bearing in mind that the pipe size must be compatible with the die diameter.

THE REPAIR PROCEDURE IS AS FOLLOWS:

© 2025-26 KPT Piping System. All Right Reserved. | Privacy Policy