A brand new from the house of KPT, we proudly introduce KPT Thermaplus pipes and fittings plumbing system for firefighting lines various other applications. The outer and middle layer of the pipes is being made of Thermaplus FR Composite Pipes & Fittings material which can easily with stand flames for ensuring safe passage for the public at large and excellent performance with long life in direct sunlight having UV resistant on the upper layer. The middle layer glass fiber reinforced with in the two layer of PPRC act as an agent to reduce extension capability and produce durability to high pressure at high temperature. This plumbing system is ideal for all kinds of firefighting lines, Hotels, Malls, Industries, Schools, Residential Apartments

etc.

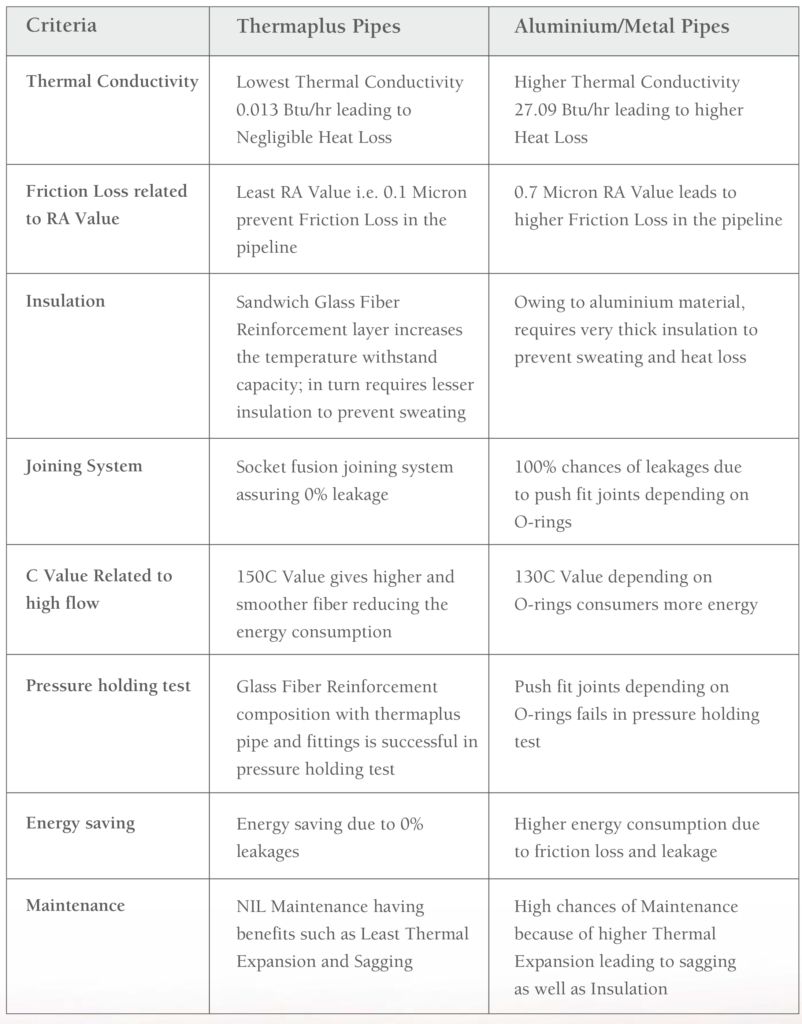

KPT is leading Composite Pipe Manufacturers in India, our Thermaplus piping is preferably advisable to use in highly corrosive chemicals, higher and lower temperature applications as well as all types of process and utility applications, soft water, raw water, R.O water, D. M water etc. KPT brand Thermaplus Pipes and Thermal Fittings are having lot of advantages which can overcome the issues like leakages, pressure drop and corrosion – erosion in Meal Piping. Those are as under:

Thermaplus pipe and fittings provides leak proof joining throughout the life of pipes and fittings, because the joining system used in Thermaplus pipe and fittings is socket fusion welding where the outer diameter of the pipe and the inner diameter of fitting are heated and the joint is made. And there are two main advantages of this joining system, firstly the leak proof joining is created and secondly there is no ring created in the pipe which prevents scaling in the piping, wherein metal pipe; there is a threaded type of joint which creates leakages and increases the chances of scaling in the pipe. And in case of any plastic pipe; the joining system used is the Butt Welding where there is a ring created inside the pipe which will act like a barrier to any fluid or chemical which passes in the pipes and it also causes scaling in the pipes.

Thermaplus pipe and fittings is a non-metallic technology for industrial application. Generally industries use traditional metal piping system where they face huge problem of corrosion and rust as there was no other option which was later a cause for creation of leakage in the piping system but with Thermaplus pipe and fittings; you can have rust and leak proof piping.

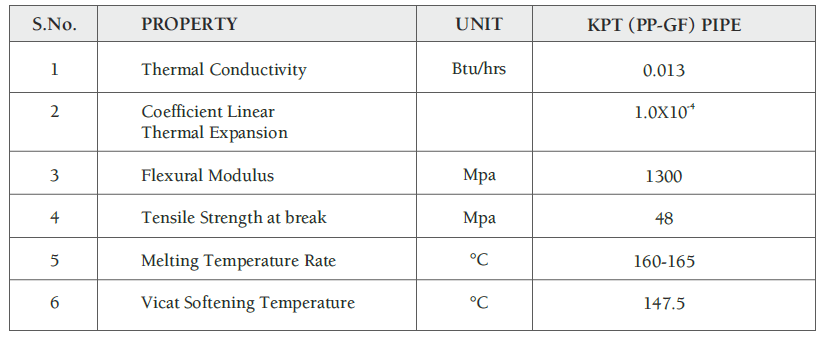

One of the major problems faced by any industrial user is the temperature loss. Many applications in which it becomes necessary to maintain the temperature; companies face problem of temperature loss and sweating from the piping in metal and any plastic pipes and that forces them to have a thick insulation which is very expensive and also maintenance leading. But with Sandwich Glass Fiber Technology in Thermaplus pipe and fittings; there is no temperature loss, as the thermal conductivity in Thermaplus pipe and fittings is 0.024 Btu/hr ftoF, which is 1700 times lesser compare to metal pipes and 11 times lesser compared to any plastic pipes. So the middle GLASS FIBER layer acts as insulation to the pipe. Hence, it requires minimum insulation.

The roughness is calculated in terms of the RA Value and the RA Value of Thermaplus pipe and fittings is 0.07 Micron which is very much lesser compared to any metal pipes. And with higher RA Value there is more friction in the piping and hence in any metal piping there is lot of friction which affects the flow in the piping and it also creates scaling but Thermaplus pipe and fittings have smoother inner surface so there is no chance of friction and it gives very easy and smooth flow in the piping. Moreover there is no possibility of scaling in our piping.

1. Absolutely Flame Retardant V2 Grade Pipes & fitting.

2. Almost double strength owing to Glass Fiber Reinforcement Technology.

3. Higher temperature resistance owing to inbuilt Glass Fiber Reinforcement layer.

4. Very less Thermal Expansion because of Sandwich Glass Fiber Reinforcement Layer.

5. 50% less clamping requirement compared to PPR Pipes due to Glass Fiber Reinforcement Layer.

6. NIL Maintenance having benefits such as Least Thermal Expansion and Sagging.

7. Owing to Sandwich Glass Fiber Reinforcement layer, very less sagging gives nice and Aesthetic View

to the pipeline

8. Negligible Friction loss owing to higher C Value – 150 and Least RA Value – 0.1 Micron

9. Socket Fusion joining system guaranteeing 100% Leak Proof element in pipes.

10. No obstruction creation inside pipeline which leads to least Pressure Drop.

11. 100% Non Corrosive product provides absolutely Corrosion Free piping which does not create any leakage.

12. Up to 5% energy saving owing to least RA Value, higher C Value and 100% leak proof element

13. Higher flow rate 25% (bigger ID)

14. Energy saving 25%

15. Thermaplus pipes reduce passive heat loss by around 20% for non-insulated pipe.

16. Chemicals and acid applications

17. 4X lower linear thermal expansion

1. Absolutely Thermaplus FR Composite Pipes & Fittings V2 Grade Pipes & fitting.

2. Almost double strength owing to Glass Fiber Reinforcement Technology.

3. Higher temperature resistance owing to inbuilt Glass Fiber Reinforcement layer.

4. Very less Thermal Expansion because of Sandwich Glass Fiber Reinforcement Layer.

5. 50% less clamping requirement compared to PPR Pipes due to Glass Fiber Reinforcement Layer.

6. NIL Maintenance having benefits such as Least Thermal Expansion and Sagging.

7. Owing to Sandwich Glass Fiber Reinforcement layer, very less sagging gives nice and Aesthetic View

to the pipeline

8. Negligible Friction loss owing to higher C Value – 150 and Least RA Value – 0.1 Micron

9. Socket Fusion joining system guaranteeing 100% Leak Proof element in pipes.

10. No obstruction creation inside pipeline which leads to least Pressure Drop.

11. 100% Non Corrosive product provides absolutely Corrosion Free piping which does not create any leakage.

12. Up to 5% energy saving owing to least RA Value, higher C Value and 100% leak proof element

13. Higher flow rate 25% (bigger ID)

14. Energy saving 25%

15. Thermaplus pipes reduce passive heat loss by around 20% for non-insulated pipe.

16. Chemicals and acid applications

17. 4X lower linear thermal expansion

Technical Data of KPT Thermaplus Pipes

1. Firefighting lines

2. Chemical and acid Plants

3. Cooling and chilled water

4. Hydraulic Oil (Pressure 20kgf)

5. Geo thermal application

6. Recycle water

7. Air conditioning

8. Potable water hot and cold

9. Solar Heaters application

10. Liquid foods

11. Watering system for greenhouse and gardens

12. Transportation aggressive fluids

13. Water purifying plants

14. Radiator heating

15. Traditional heating system

16. Air distribution and compressed air system