15 Apr Next-Gen Plumbing: The Science and Engineering of PPR Pipes

Plumbing technology has evolved significantly over the years, leading to more efficient, durable, and sustainable piping solutions. One of the most revolutionary advancements in this field is Polypropylene Random Copolymer (PPR) pipes and fittings. These pipes have transformed the way plumbing systems function, offering unmatched durability, heat resistance, and chemical stability.

KPT Pipes, a leader in PPR pipe manufacturing, has set the benchmark for high-quality plumbing solutions in India. With a strong focus on innovation and engineering excellence, KPT Pipes ensures that every product meets the highest standards of performance and longevity.

In this blog, we will delve deep into the science and engineering behind PPR pipes and fittings, exploring their material composition, structural advantages, applications, and why they are considered the next-generation plumbing solution.

The Science Behind PPR Pipes and Fittings

What is PPR? The Material Composition

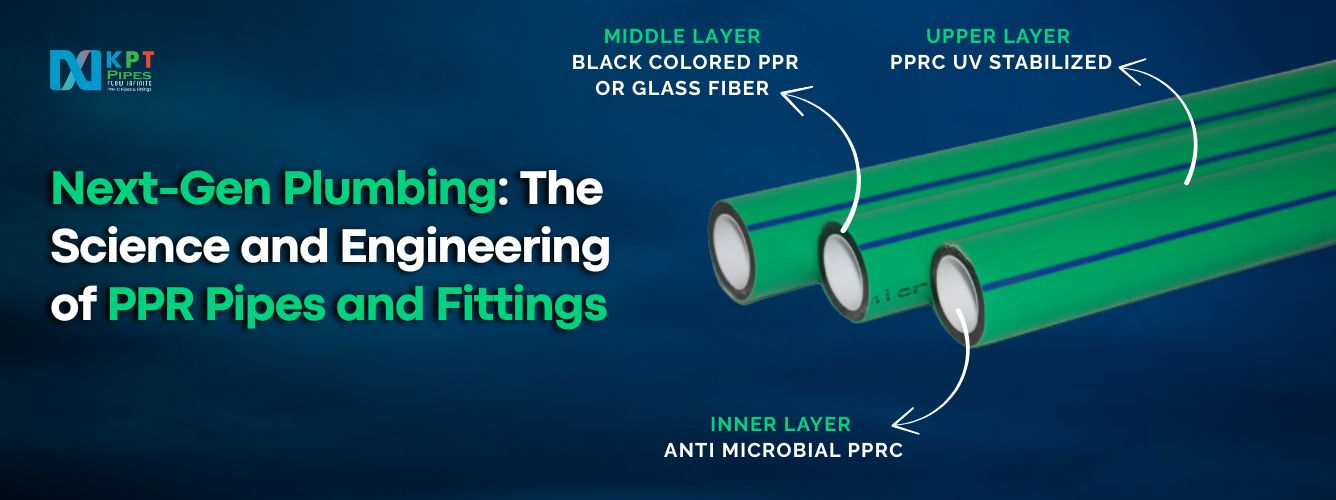

PPR (Polypropylene Random Copolymer) is a thermoplastic polymer known for its exceptional mechanical strength, chemical resistance, and thermal stability. It consists of polypropylene molecules arranged in a random pattern, which enhances its flexibility, durability, and overall structural integrity. This unique molecular structure provides several advantages over traditional plumbing materials.

- High Impact Resistance: PPR pipes can endure mechanical stress and external pressure, making them an excellent choice for high-pressure plumbing applications in residential and industrial settings.

- Thermal Stability: These pipes can maintain their structural integrity even at extreme temperatures up to 95°C, making them ideal for both hot and cold water systems in homes and industries.

- Corrosion Resistance: Unlike metal pipes, PPR remains chemically inert and does not corrode over time, ensuring a clean, uncontaminated water supply and long-term reliability.

- Low Thermal Conductivity: The material has low heat transfer properties, reducing energy loss in hot water plumbing and improving overall system efficiency.

Engineering Excellence: How PPR Pipes Are Manufactured

Advanced Manufacturing Process of PPR Pipes

The production of PPR pipes involves multiple stages of high-precision engineering, ensuring durability and efficiency. From raw material selection to rigorous quality testing, every step is controlled to enhance strength, leak-proof performance, and longevity. This advanced process makes PPR pipes ideal for modern plumbing applications.

- Raw Material Selection: High-grade polypropylene random copolymer (PPR-C) is chosen for its thermal resistance, chemical stability, and mechanical strength. This ensures that PPR pipes remain corrosion-resistant, durable, and suitable for high-pressure applications.

- Extrusion Process: The PPR material is melted and extruded using precision-engineered molds under strict controls. This ensures uniform thickness, smooth internal surfaces, and enhanced mechanical integrity, improving flow efficiency and reducing friction losses.

- Molecular Orientation: As the pipes cool, the molecular structure aligns to enhance flexibility, tensile strength, and impact resistance. This controlled cooling process ensures that PPR pipes maintain their shape and performance even under extreme conditions.

- Quality Testing: Each batch undergoes pressure, heat, and impact tests to ensure compliance with international plumbing standards. Only after passing these tests are PPR pipes deemed safe, durable, and reliable for residential, industrial, and commercial applications.

With meticulous engineering and strict quality control, KPT Pipes delivers superior, leak-proof, and long-lasting PPR pipes, setting new benchmarks in next-gen plumbing solutions.

Structural Advantages of PPR Pipes Over Conventional Pipes

Superior Strength and Longevity

PPR pipes have an exceptional lifespan of 50+ years, significantly outperforming traditional materials like PVC, CPVC, and metal pipes. Their high molecular weight and strong intermolecular bonds provide superior impact resistance and durability. This makes them an excellent choice for high-pressure plumbing and industrial applications, ensuring long-term performance.

Leak-Proof Joints with Fusion Welding

Unlike traditional pipes that rely on threaded, solvent-based, or mechanical joints, PPR pipes use heat fusion welding. This process thermally bonds the pipes and fittings, creating a single, homogenous structure that eliminates leaks and weak points. As a result, the plumbing system remains robust, maintenance-free, and resistant to joint failures.

Chemical and Corrosion Resistance

Unlike metal pipes, which react with water, leading to rust and scale buildup, PPR pipes remain chemically inert. They can safely transport aggressive fluids, acids, and bases without degradation, ensuring clean water supply and longevity. This makes PPR pipes an ideal choice for industrial and chemical applications.

High Temperature and Pressure Endurance

PPR pipes can withstand temperatures up to 95°C and pressures up to 20 bar, making them ideal for high-pressure plumbing systems, industrial applications, and HVAC systems. Their high thermal tolerance prevents warping, cracking, and degradation, even in extreme conditions. These features ensure long-lasting performance and reliability in various demanding environments.

Environmentally Sustainable and Non-Toxic

PPR pipes are 100% recyclable, free from harmful chemicals, and contribute to eco-friendly plumbing solutions. Their non-toxic composition ensures safe drinking water supply, making them suitable for residential and commercial plumbing. Additionally, their production process reduces carbon footprint, aligning with sustainable building standards.

Applications of PPR Pipes and Fittings

Residential Plumbing Systems

PPR pipes are widely used in homes for hot and cold water distribution, ensuring leak-free and contamination-free plumbing. Their high resistance to corrosion, pressure, and temperature changes makes them ideal for long-term household plumbing. With their non-toxic and durable properties, they ensure a clean and safe water supply for residential use.

Industrial and Chemical Transport

Industries rely on PPR pipes for transporting chemicals, acids, and aggressive fluids, as they remain chemically inert and corrosion-resistant. Their ability to handle high pressure and extreme temperatures makes them indispensable in factories, chemical plants, and pharmaceutical industries. These pipes help ensure safe and efficient fluid transportation in industrial applications.

HVAC and Heating Systems

PPR pipes are extensively used in heating, ventilation, and air conditioning (HVAC) systems due to their thermal insulation properties. They help maintain energy efficiency by minimizing heat loss and reducing overall energy consumption. This makes them a preferred choice for modern HVAC systems in commercial and residential buildings.

Agriculture and Irrigation

For modern irrigation systems, PPR pipes provide high water flow capacity, UV resistance, and leak-free performance. Their durability allows them to withstand harsh environmental conditions, pressure variations, and prolonged exposure to sunlight. This ensures efficient and sustainable water distribution for farms and greenhouses.

Hospital and Pharmaceutical Piping

The pharmaceutical industry and hospitals require hygienic and contamination-free piping systems. PPR pipes ensure the safe transportation of purified water, medical gases, and sensitive fluids, preventing bacterial growth. Their non-reactive and sterile properties make them ideal for healthcare and pharmaceutical applications.

The Future of PPR Pipes: Innovation and Growth

Smart Plumbing with IoT Integration

Future developments in PPR pipes include smart monitoring systems that detect leaks, temperature changes, and pressure variations in real time. These systems use IoT-enabled sensors to provide data on plumbing conditions, ensuring efficient maintenance and quick fault detection. This innovation will transform plumbing into a highly efficient and automated system.

Green Building Certifications and Sustainable Growth

PPR pipes align with LEED and BREEAM green building standards, promoting eco-friendly and sustainable construction practices. Their recyclable and non-toxic nature contributes to reducing environmental impact, making them essential for green architecture. As global construction trends move towards sustainability, PPR pipes will play a crucial role in future building projects.

Advanced Material Innovations

New research in nanotechnology and polymer engineering is leading to the development of self-repairing and antimicrobial PPR pipes. These innovations will enhance pipe durability, prevent bacterial contamination, and improve overall efficiency. With continued advancements, next-generation PPR pipes will offer even greater reliability and safety in plumbing systems.

Conclusion

The science and engineering of PPR pipes and fittings have positioned them as the most advanced plumbing solution available today. Their superior durability, leak-proof installation, high-pressure resistance, and eco-friendly attributes make them the ideal choice for modern plumbing systems.

KPT Pipes continues to lead the industry with cutting-edge innovations in PPR pipe technology, ensuring that homes, industries, and commercial spaces benefit from next-generation plumbing solutions.

For high-quality PPR pipes and fittings, trust KPT Pipes, a pioneering pipes manufacturing company in India that is setting new industry standards.

FAQs About PPR Pipes and Fittings

Q1. What makes PPR pipes better than PVC or CPVC pipes?

Ans: PPR pipes are more durable, resistant to high temperatures, and have a longer lifespan compared to PVC and CPVC pipes. Their heat fusion jointing system makes them leak-proof, unlike PVC pipes that require solvent-based adhesives.

Q2. Can PPR pipes be used for hot water applications?

Ans: Yes, PPR pipes can handle temperatures up to 95°C, making them ideal for hot water plumbing, heating systems, and industrial fluid transport.

Q3. Are PPR pipes environmentally friendly?

Ans: Yes, PPR pipes are 100% recyclable, non-toxic, and free from harmful chemicals, making them a sustainable choice for modern plumbing systems.

Q4. How long do PPR pipes last?

Ans: PPR pipes have an estimated lifespan of 50+ years, thanks to their corrosion resistance, high-impact strength, and thermal stability.

Q5. Where can I buy high-quality PPR pipes in India?

Ans: For the best PPR pipes and fittings, choose KPT Pipes – a leading pipes manufacturing company in India, known for its superior quality and engineering excellence.