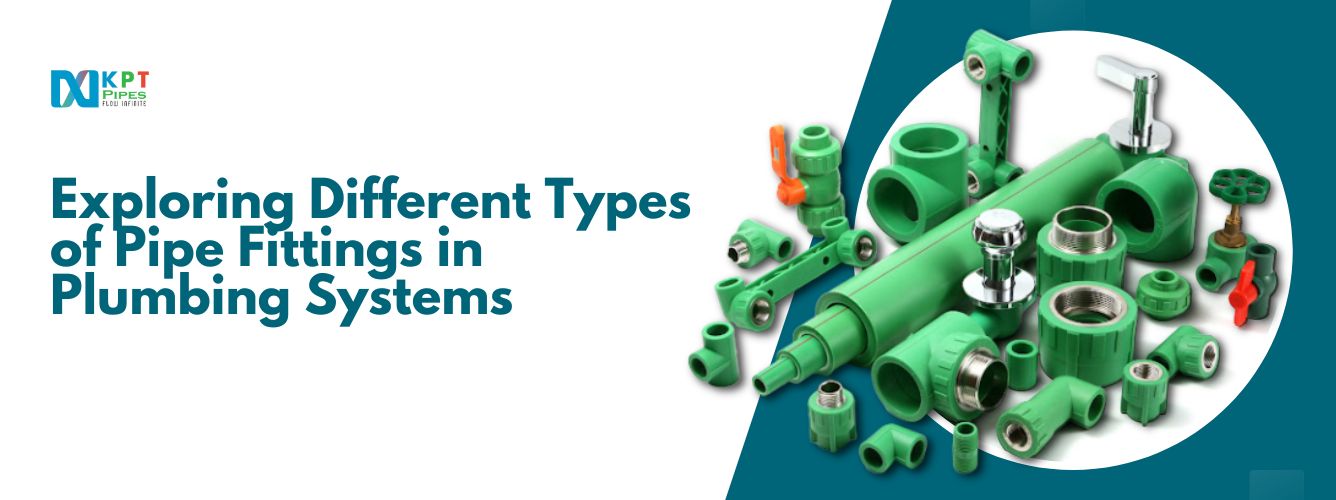

23 Jan Exploring Different Types of Pipe Fittings in Plumbing Systems

When it comes to efficient plumbing systems, pipe fittings play an indispensable role. These essential components connect pipes, allowing for smooth flow, direction changes, and a variety of other functions critical to residential, commercial, and industrial plumbing. Whether you’re a seasoned plumber or a homeowner exploring renovation options, understanding the types and uses of plumbing fittings is vital for designing a robust and efficient system.

In this blog, we’ll delve into the various types of pipe fittings, their uses, and why PPR (Polypropylene Random Copolymer) stands out as one of the best materials for pipes and pipe fittings In India. We will also address several commonly asked questions to assist you in making well-informed choices.

What Are Pipe Fittings?

Pipe fittings connect different sections of pipe in a plumbing system. They change the direction of the pipe, join multiple pipes, or control the flow of water, gas, or other fluids. Manufacturers produce pipe fittings in various shapes, sizes, materials, and designs to meet different plumbing needs. Common types of pipe fittings include elbows, tees, couplings, reducers, and more.

Each type of fitting serves a specific function, depending on the requirements of the plumbing system. Let’s dive into the different types of pipes fittings and their roles in plumbing systems.

Types of Pipe Fittings in Plumbing Systems

Elbows: Elbows alter the direction of a pipe. They come in angles of 45°, 90°, and sometimes 22.5°, enabling plumbers to navigate plumbing layouts effectively. Plumbers use elbows in both residential and commercial applications. Common materials for elbows include PVC, PPR, and stainless steel.

Tees: Tee fittings, shaped like the letter “T,” branch off a main pipeline. They connect pipes of the same diameter or reduce one branch with a reducing tee. Tees create efficient layouts in water supply systems.

Couplings: Couplings connect two pipes of the same or different diameters. Plumbers use them to repair broken pipes or extend existing pipelines. Couplings are available in threaded, compression, and slip-fit variants.

Reducers: Reducers join pipes of varying diameters.

- Concentric Reducers: Align the centerline of pipes and function primarily in vertical systems.

- Eccentric Reducers: Offset the connection to prevent backflow, making them suitable for horizontal systems.

Unions: Unions assemble and disassemble pipes without causing system damage. They work well in areas requiring regular maintenance or future modifications.

Adapters: Adapters connect pipes made from different materials or with different diameters. For instance, plumbers use male or female adapters to link threaded pipes to non-threaded ones. Adapters prove useful when connecting or joining pipes of varying sizes.

Caps and Plugs: Caps seal the ends of pipes from the outside, while plugs seal them from the inside.

Cross Fittings: Cross fittings join four pipes at a single junction. Plumbers often use them in irrigation systems and setups requiring multiple outlets.

Valves: Valves regulate the flow of liquid or gas within a pipeline. Examples include gate valves, ball valves, and check valves, which ensure system regulation and safety.

Flange Fittings: Flange fittings securely connect two pipes or a pipe to equipment. These fittings bolted together, create strong, leak-proof seals. Industries like chemical processing rely on flange fittings for robust, reliable connections.

Bushings: Bushings reduce the diameter of a pipe, allowing smaller pipes to connect to larger ones. They come in configurations like female-to-male or male-to-female, depending on the application.

Pipe Clamps: Pipe clamps secure pipes to surfaces or structures, preventing movement, vibrations, or damage. They come in materials like metal and plastic, tailored to specific applications.

Tank Connectors: Tank connectors link pipes to storage tanks or reservoirs, ensuring secure, leak-proof connections between the tank and plumbing system.

Bypass Bend: Bypass bends create bypass loops in pipelines, allowing fluid to bypass sections for maintenance or cleaning.

Uses of Different Pipe Fittings In Various Applications

Elbows Use: Elbows redirect fluid flow around obstacles, such as corners or when transitioning between vertical and horizontal pipes. They commonly function in water supply systems, drainage, and HVAC systems.

Tees Uses: Tees split the flow of water, gas, or other fluids into multiple directions. They play a crucial role in water distribution systems, gas lines, and irrigation networks, supplying multiple outlets from a single source.

Couplings Use: Couplings join two pipes of the same size or connect pipes of varying diameters. Plumbers, heating system technicians, and gas distributors rely on couplings to ensure secure and tight connections.

Reducers Use: Reducers create smooth transitions between pipes of different sizes, preventing flow issues and optimizing system performance. Water supply systems, sewage lines, and gas pipelines rely on reducers for efficient operation.

Unions Use: Unions allow quick disassembly or maintenance without cutting or damaging pipes. They typically connect components like pumps, filters, and valves.

Adapters Use: Adapters connect pipes of different materials or sizes, such as PVC pipes to metal ones. They ensure compatibility and seamless connections in diverse piping systems.

Caps and Plugs Use: Caps and plugs seal off unused or open pipe ends during construction, maintenance, or testing. They prevent leaks, maintain pressure integrity, and protect pipes from contamination.

Cross-Fittings Use: Cross-fittings connect multiple branches at a single junction. Irrigation networks, water supply systems, and heating systems use them to distribute fluids to various outlets.

Valves Use: Valves control the flow of liquids or gases, essential for system regulation. Gate valves provide on/off control, ball valves enable precise flow control, and check valves prevent backflow in plumbing, HVAC, and industrial systems.

Flange Fittings Use: Flange fittings connect large-diameter pipes or systems requiring frequent disassembly. Industrial and chemical processing plants, water treatment facilities, and large-scale pipelines rely on them for robust, leak-proof connections.

Bushes Use: Bushings connect pipes of different sizes, especially when attaching smaller pipes to larger ones. Plumbing systems, irrigation setups, and drainage applications commonly use bushings.

Pipe Clamps Use: Pipe clamps secure and support pipes to surfaces or structures, preventing movement and damage. Water supply lines, HVAC systems, and gas pipelines use clamps to minimize stress and vibration.

Tank Connectors Use: Tank connectors create secure connections between pipes and storage tanks. They are vital in water storage, rainwater harvesting systems, and industrial water management systems.

Bypass Bend Use: Bypass bends create alternate flow paths in pipelines, allowing fluid to bypass sections during maintenance or cleaning. Filtration systems, pumps, and heat exchangers depend on them to maintain flow continuity during maintenance.

PPR: The Best Material for Pipes and Pipe Fittings in India

Why Choose PPR Fittings?

PPR (Polypropylene Random Copolymer) is increasingly recognized as one of the best materials for plumbing systems due to its durability, versatility, and efficiency. Here are some of the reasons why PPR stands out:

Corrosion Resistance: Unlike metal pipes, PPR pipes and fittings are highly resistant to corrosion caused by water, chemicals, or environmental factors. This ensures a significantly longer lifespan for plumbing systems, even in demanding conditions.

Thermal Stability: PPR can withstand high temperatures, making it suitable for hot and cold water applications. Its thermal stability ensures reliable performance in residential, commercial, and industrial plumbing systems.

Chemical Resistance: PPR pipes exhibit a high level of resistance to various chemicals, encompassing both acids and alkalis. This makes them ideal for industries that handle corrosive substances, ensuring safety and system longevity.

Durability: PPR pipes and fittings are lightweight yet exceptionally durable, withstanding high pressure and impact. They offer a lifespan of over 50 years under optimal conditions, reducing long-term replacement costs.

Eco-Friendly: PPR is recyclable and has a lower environmental impact compared to traditional materials like PVC or metal. Its production and disposal have minimal effects on the environment, aligning with sustainability goals.

Easy Installation: The fusion welding method used for PPR pipe fittings creates leak-proof, seamless joints. This reduces maintenance, ensures reliability, and minimizes installation time and costs.

Common Applications of PPR Pipes and Fittings

- Residential Plumbing Systems: These are used in homes for hot and cold water supply.

- Commercial Water Supply: Ideal for office buildings, hotels, and shopping complexes.

- Industrial Fluid Transport: Handles corrosive chemicals and high-pressure fluids.

- Heating and Cooling Systems: Suitable for underfloor heating and chilled water lines.

- Agricultural Irrigation: Used in irrigation systems due to its durability and resistance.

Advantages of Using High-Quality Plumbing Fittings

Leak Prevention: High-quality fittings ensure secure connections, minimizing the risk of leaks that could lead to water wastage and structural damage. This characteristic is particularly important in systems that operate under high pressure.

Longevity: Durable materials like PPR, stainless steel, and brass significantly extend the lifespan of plumbing systems. Investing in high-quality fittings ensures reliable performance for decades.

Ease of Installation: Precision-engineered fittings are easier to install and require minimal tools. This reduces labour costs and ensures a faster project turnaround without compromising quality.

System Efficiency: Properly chosen fittings optimize the flow of water or gas, preventing blockages or pressure drops. This enhances the overall efficiency and performance of the plumbing system.

Cost Savings: Investing in premium fittings reduces the need for frequent repairs or replacements. Over time, this leads to substantial cost savings and fewer service disruptions.

Tips for Choosing the Right Pipe Fittings

Consider the Material: Choose a material compatible with your application, such as PPR for water supply or stainless steel for corrosive environments. Selecting the appropriate material guarantees both longevity and optimal performance of the system.

Know the Size: Ensure the fitting matches the pipe diameter for a secure and leak-proof connection. Using mismatched sizes can lead to system inefficiencies and increased maintenance needs.

Check for Standards: Look for fittings that meet industry standards for quality and safety, such as ISO or ASTM certifications. Compliance with standards ensures reliability and long-term performance.

Consult Experts: Seek professional advice for complex systems or specific requirements. Experts can recommend the best fittings and materials based on the application and environmental factors.

Conclusion

Understanding the types of pipe fittings and their applications is crucial for designing an efficient plumbing system. From basic elbow joints to advanced PPR fittings, the choice of material and design significantly impacts the durability and performance of the system. PPR, with its exceptional properties, has emerged as a leading material, offering reliability and sustainability for modern plumbing needs.

Frequently Asked Questions (FAQs)

Q1. What are pipe fittings used for?

Ans: Pipe fittings are used to connect, redirect, regulate, or terminate pipes in a plumbing system, ensuring smooth flow and proper system functionality.

Q3. Why is PPR a good choice for plumbing fittings?

Ans: PPR is durable, corrosion-resistant, and eco-friendly. Its ability to endure elevated temperatures and pressures renders it suitable for a wide range of plumbing applications.

Q3. How do I choose the right pipe-fitting material?

Ans: Consider the type of fluid, temperature, pressure, and compatibility with other system components to select the appropriate material.

Q4. What is the difference between a coupling and a union

Ans: A coupling permanently connects two pipes, while a union allows for easy disassembly without damaging the system.

Q5. Are plastic pipe fittings as durable as metal ones?

Ans: Plastic fittings like PPR and PVC are highly durable for specific applications, especially in corrosion-prone environments, but metal fittings are preferred for high-pressure and industrial uses.